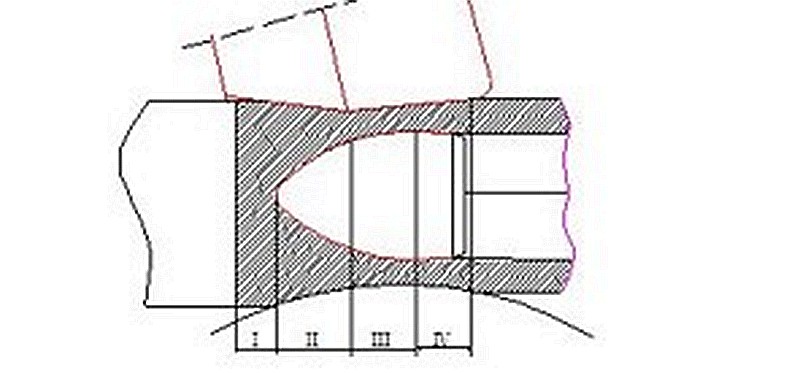

Zone I is called the piercing preparation zone (rolling billet tube zone). The main function of Zone I is to prepare for the piercing and successfully achieve the second bite. The deformation characteristics of this section are: due to the taper of the cone surface of the roll entrance, the tube blank advancing along the piercing direction is gradually compressed in diameter, and the compressed part of the metal flows laterally, the billet wave surface is round into an oval, and a part of the metal extends axially which mainly causes the surface metal to deform, so a "trumpet" shaped depression is formed at the front end of the billet. This dip and centering hole ensure that the nose of the plug is aligned with the center of the billet, thus reducing the uneven wall thickness of the hollow pipe front.

Zone II is called the piercing zone, that is material from the solid billet into a hollow tube, the length of the zone is from the metal and the plug to the plug circular cone. The deformation characteristics of this section are mainly wall thickness compression. Because the distance between the roll surface and the plug surface is gradually reduced, the hollow pipe wall thickness is rotated while being compressed. Therefore, it is a continuous rolling process, and the deformation parameters of this section are expressed by the relative reduction of the wall thickness. The metal being reduced on the wall thickness can also flow horizontally (expanding) and vertically (extending), but the transverse deformation is prevented by the guide Disc, and the longitudinal extension deformation is the main one. The function of the guide disc is not only to limit the transverse deformation but also to pull the metal to extend axially, and as a result of the transverse deformation, the cross section is elliptical.

Zone III is called rolling zone, the role of this zone is rolling to improve the dimensional accuracy of the tube wall and the inner and outer surface quality, because the plug bus and the roll bus are approximately parallel, so the amount of pressure is very small, mainly plays the role of leveling. The cross section of the rolled piece is also elliptical in this section and gradually decreases.

Zone IV is called the circle zone. The function of this area is to gradually reduce the pressure on the diameter of the oval capillary to zero by rotating the roll, and turn the capillary round, the length of this area is very short, and the deformation in this area is actually a plastic bending deformation of the hollow capillary without a plug, and the deformation force is also very small.

In the deformation process, the four sections are interrelated and carried out at the same time. The deformation process of metal cross section is the process of changing from circle to ellipse and then back to circle.

To provide comprehensive services and more valuable industrial equipment and consumptions to customers.

Get in Touch